STATE-Of-The-ART Tools & Factory Trained Techs

Our New York and Burbank facilities are outfitted with advanced optical analysis and calibration equipment, and our techs have been factory trained by Angenieux, Canon, Cooke, and ZEISS, as well as trained on Fujinon lenses.

This high level of training, sophisticated equipment, and scientific standards come together to make our optical service department so outstanding.

MTF – Our Standard of Performance Measurement

A measurement of contrast, Modulation Transfer Function, or MTF, is the most widely used scientific method of describing lens performance and the criteria by which we measure the image quality of lenses.

The Modulation Transfer Function is a measure of the transfer of modulation (or contrast) from the subject to the image. In other words, it measures how faithfully the lens reproduces (or transfers) detail from the object to the image produced by the lens.

Our Optical Test Equipment

Our MTF equipment and other optical test equipment is used regularly by our service department, led by our state-of-the-art ZEISS test equipment. All ZEISS optical devices are founded on more than 40 years of experience and are regularly used in lab and industrial production control environments at ZEISS headquarters in Oberkochen, Germany.

|

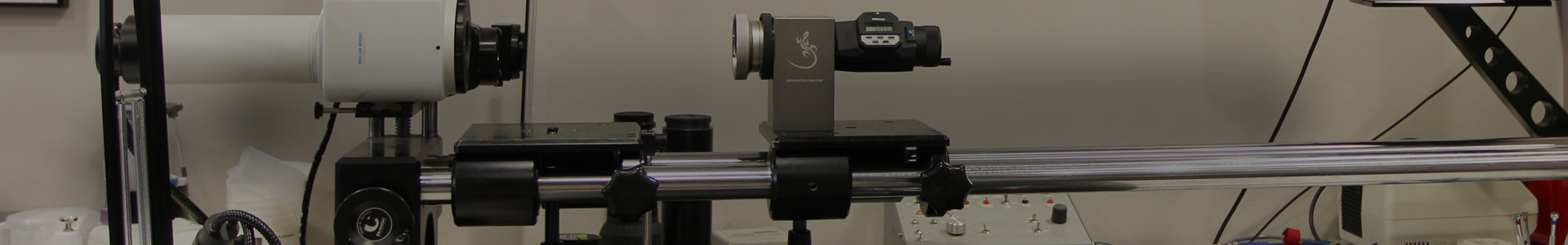

ZEISS K8 MTF SystemThe MTF-Tester K8, designed and manufactured by ZEISS, is a versatile instrument for the measurement of the Modulation Transfer Function (MTF) of any photographic or cinematography lens. MTF is an objective way of quantifying contrast at a particular resolution. The K8 measures the lens while it is focused at infinity, and it can measure both in the center (axis) and all the way to the corners of the frame (field). The measurement is based on slit line image analysis and is performed by custom software in real time at three different spatial frequencies, generally 10, 20 and 40 lp/mm. Real time measurement allows for the fine-tuning of lenses during assembly or service. The K8 not only measures MTF but also easily detects field curvature, chromatic aberration, and whether the optics are properly aligned. |

|

ZEISS K9 MTF SystemThe On-Axis MTF Tester K9 is a universal, modular instrument especially suitable for the routine service and repair of lenses. The K9 works on the same measurement principle as the K8 and uses similar custom software. While the K8 can only measure at infinity, the K9 can measure at infinity and also at fixed finite focus distances, like 6ft or 2m, but only on-axis. This allows a quick check of back focus and focus scale accuracy in one setup, with one micron (1/1000th millimeter) precision. Any backlash in the focus mechanics, as well as focus shift induced by changing aperture, can be measured precisely and quickly. Glass plates can be inserted ahead of the measurement system to simulate the IR/OLPF packs of digital cinema cameras. This can help to compensate lenses whose focus scales may be inaccurate on a particular camera at a particular T-stop, an invaluable tool for modern digital cinematography. |

|

ZEISS T-Stop TesterThe T-Stop Tester is used to measure the effective transmission aperture of photographic and cinematographic lenses and is particularly suitable for lens repair. Since the transmission corrected T# aperture (as opposed to the geometric f# aperture) is decisive for proper exposure of a film or digital cine camera, the T-Stop tester displays EV values rather than f# values. The T-Stop tester is accurate to 0.01 EV and is paired with a very precise master lens that is used to calibrate the tester every time it’s used. |

|

zeiss torque testerAt the end of the repair cycle, or when a problem is suspected with a lens, the Torque Tester is used to precisely measure the force required to turn the scale rings (focus, zoom and t-stop). Adjustments can then be made to bring the scale rings to their factory specified tension settings for optimum and consistent performance. All of the above ZEISS tools are the same instruments used for quality control at the factory in Oberkochen, Germany. |

|

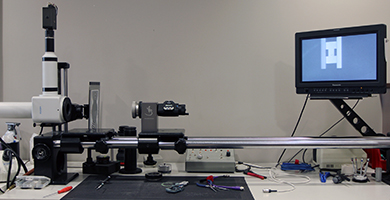

Chrosziel/Gecko-Cam Mk. III 45S AutocollimatorThe MK. III 45S Autocollimator is the industry standard for back focus adjustment. Our hybrid unit employs the original Chrosziel architecture with Gecko-Cam’s interchangeable mount system. The autocollimator head uses a rangefinder system with two parallel collimator tubes, each having a different reticle. The image of the two reticles aligns only when the image is exactly in focus. The image is bounced off the carbide tip of a high precision micrometer that is used to measure the position of the image plane and determine how much the lens has to be corrected to bring the image into focus on the film or digital sensor. Lens mounts supported: ARRI-PL, Sony-B4 (2/3″ 3CCD), Canon EF, Nikon F, and PV-35. The image is observed on a HD monitor for ease of operation. Cameras can also be mounted to test flange depth, especially important on digital cinema cameras. |

|

Gecko-Cam Lens Test ProjectorAfter all the advanced calibration is complete, the eye of an experienced lens technician is the final judge of overall lens quality. The Gecko-Cam Lens Test Projector is utilized to project a precision test reticle, with spherical and anamorphic targets, through the lens (essentially, imaging in reverse). When the projected image is observed in a dark room, problems such as flare, uneven asymmetric focus, image geometry, and format coverage can all be clearly observed. Color fringing can also be clearly seen and subjectively quantified. The image plane can also be moved with 0.001mm accuracy to check focus scales and measure field curvature. The Gecko-Cam device is the industry standard for lens test projection and can project lenses that cover the full 24mm x 36mm image size. Interchangeable mounts with built-in OLPF are available for additional testing. |

|

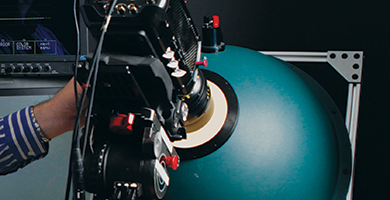

Integration SphereThe Integration Sphere is utilized for the precise “shading” of a specific lens to a specific camera. All lenses affect the evenness of light being transmitted through them. The function of the Integrating Sphere is to diffuse light in a uniform way, thus allowing for precise adjustment of the evenness of light through the lens across the sensor of the camera. |